Everything that You Must Know About Industrial Air Filtration Systems

Pollutants such smoke, fumes, dust, and airborne contaminants are common in industries. Employee health is impacted by their inadequate industrial air purification system. Recognize that it also impacts product quality and the lifespan of your machinery.

Eliminating environmental pollutants is crucial in industrial settings. As the breeze in your home goes through its many premium cleaners.

You can remove dangerous particles from it by using the appropriate solution. As a result, you’ll be able to protect the staff and the facility.

What’s Industrial Air Filtration?

In many industrial applications, vent quality is an important consideration. This will guarantee excellent product integrity, reduce pollution, and eventually increase product safety.

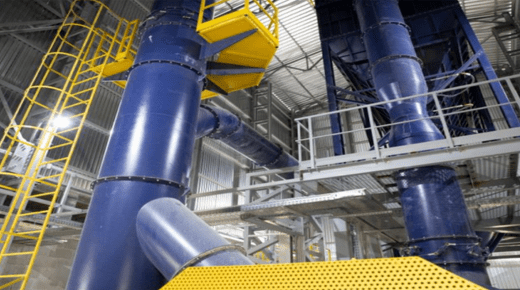

This is accomplished by manufacturers through the integration of filtration devices into industrial operations. This improves the ventilation quality in a system or area by removing solid particles and molecular pollutants.

Usually consists of a strong frame that surrounds a filter medium. To stop frame-media leaks, it’s hermetically sealed. This is incorporated by manufacturers into dryers and compression systems – visit KAWEHA Germany for more details.

How does it work?

Such filters are being used more frequently because of the increasing demand for dry, clean compressed air in various applications. Regretfully, suitable vent quality for various applications doesn’t always equate availability. Filters take out collected material while eliminating moisture that allows contaminants to flourish and corrode.

Ventilation from the compressor’s intake to the dryer and screen as part of the general operating concept. Debris, grease, filth, and other impurities are therefore trapped.

Sending the resulting air to a coalescing filter, another dryer further reduces its moisture content. As a last step in the purification process. This removes water, oil, and aerosol contaminants before moving on to another particulate filter.

Importance

- It’s employed to improve the quality of the aerate within a factory or in certain sections where particles, fumes, or vapors are produced by the process.

- In factories that produce or manufacture goods, it’s crucial. It keeps the indoor environment safe and clean while safeguarding your staff and plant assets. Your company will greatly profit from this since it helps to prolong the lifespan of electronic equipment.

- Additionally, a well-designed filtering system reduces the need for HVAC systems. Hence minimizing energy costs for your business during the cooling and heating seasons.

Types of Air Filters

High-Efficiency Particulate Air (HEPA)

99.97% of pollutants and particles as tiny as 0.3 microns are captured by them. Commercial applications and residential applications do overlap. It often has higher MERV scores and is bigger.

The MERV scale goes from 1 to 20.

It evaluates a filter’s capacity to hold big particles with diameters between 0.3 and 10 microns. The smaller particulates it can catch, the higher the rating. Visit https://theory.labster.com/de/hepa_filter/ for more details.

Hospitals are an example of commercial settings where MERV 16–20 rated filters are used. Operators in cafeterias and restaurants may select filters rated between MERV 8 and 14.

UV Light

It uses short-wave UV light to destroy germs and viruses that are carried by the wind. The almost invisible lightbulb that emits the light usually needs to be changed once a year. Extensively utilized in medical facilities.

The filters are perfect for getting rid of bacteria, aerosols, mold spores, and allergies. These are harmful to your health and can cause respiratory illnesses.

While they effectively eradicate dangerous bacteria and viruses. When it comes to getting rid of contaminants like dust, grime, and dander, UV radiation is less effective.

They’re typically used in conjunction with HEPA filters as a component of an extensive filtration system because of this. This will enable you to combat several flying debris at once.

Fiberglass

Another name for them is spun glass filters. These are a reasonably priced solution primarily intended to shield your unit from large particle damage.

They can capture some dust, debris, and allergies. This can lower the quality of the aerate within. Nonetheless, not ones that exist as little particles.

Pleated

There are reusable and disposable versions of pleated filters. They’re reasonably priced when purchased. Usually composed of cotton and polyester. This is designed to collect dust, allergens, grime, and other airborne contaminants – read more; using a folded, accordion-style construction.

More surface area is offered by the pleats than by non-pleated choices. This is to guarantee that throughout the filtration process, more particles are eliminated.

Although their affordability and efficacy against pollutants are significant benefits. The fact that they force airborne by your HVAC system is their most obvious drawback. The unit has to work more and less effectively as a result.

Factors to Consider When Selecting an Industrial Air Filtration System

Size

The CFM rating must be determined by the customer in order to select the best kind for a particular application. The space’s size is divided by the AER to determine this rating. Depending on the application, this changes.

Installation

Customers need to choose an installation-friendly system. However, it also depends on the available space’s size and possible location. Not to overlook the availability of alternative techniques, including HVAC in the same vicinity.

Furthermore, it’s imperative to take into account the system’s mobility. This is a result of the possibility of corporate expansion, modification, or relocation. Handling mobile filtration devices would be less complicated than stationary ones.

Efficiency

The most popular option is high-efficiency ventilation cleansing. But the system needs to be self-sufficient and economical. It achieves a balance between performance and operating and maintenance expenses.

For systems with low horsepower ratings, experts advise minimizing operating expenses. In the same way, a self-sufficient system provides excellent performance in both hot and cold climates. Consequently, there won’t be any more expenses for heating and cooling that depend on outside ventilation.

Cost

Consumers also need to think about the price and accessibility of filters and replacements. Therefore, choosing cleaners with specified sizes and efficiency is desirable. This is to keep replacement solution expenses to a minimum.

Manufacturer’s Brand

This is dependent upon its upkeep, consumer feedback, and market repute. For manufacturing procedures and applications, this is essential. The one with the best reviews and customer satisfaction must be identified by customers.